McGill University researchers have made a significant breakthrough in developing all-solid-state lithium batteries, paving the way for safer, longer-lasting electric vehicles (EVs).

As the automotive industry increasingly turns to electric vehicles (EVs) to reduce carbon emissions, the development of better, safer, and more efficient batteries remains a top priority. Researchers at McGill University have made a notable advance in the development of all-solid-state lithium batteries, which could prove to be the next evolution in EV battery technology. This new breakthrough addresses a long-standing issue that has hindered the performance of solid-state batteries and brings the industry closer to producing longer-lasting, safer EVs.

The findings of the research, which was led by George Demopoulos, Professor in the Department of Materials Engineering, were recently published in the journal Cell Reports Physical Science.

The Need for All-Solid-State Lithium Batteries

The push to replace traditional lithium-ion batteries with all-solid-state batteries comes from a need for improved safety and efficiency. Current lithium-ion batteries, which are widely used in EVs, rely on liquid electrolytes to facilitate the movement of lithium ions. While effective, these liquid electrolytes pose safety risks, including flammability, which can lead to catastrophic failures in the event of damage or overheating.

In contrast, all-solid-state lithium batteries replace the liquid components with solid electrolytes, making them inherently safer. This advancement eliminates the risk of leakage, significantly improving battery safety. Moreover, solid-state batteries hold the potential for higher energy densities, which could result in EVs with longer ranges.

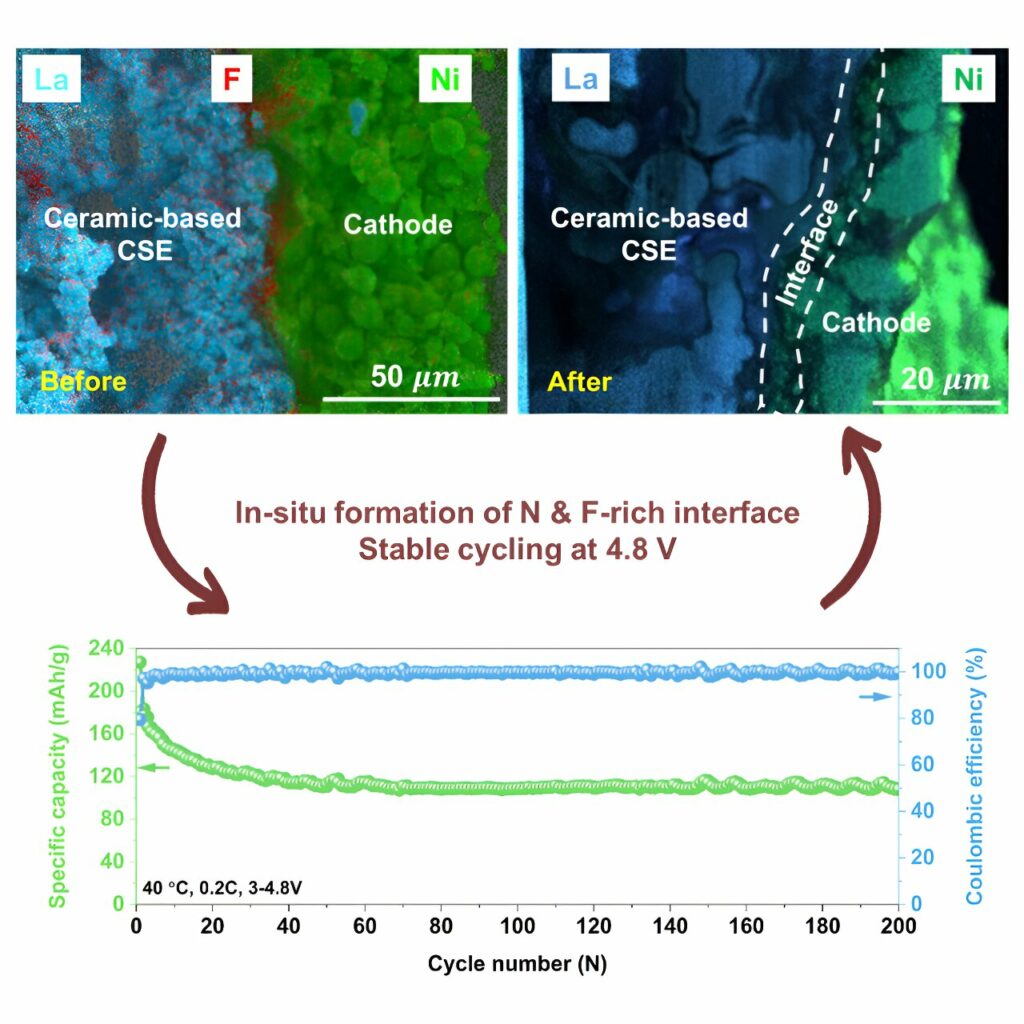

However, while solid-state batteries offer many benefits, they have faced a major roadblock in the form of interfacial resistance, a challenge that has limited their efficiency and performance. This resistance occurs at the interface between the solid ceramic electrolyte and the electrodes, reducing the battery’s ability to deliver energy.

The Breakthrough: A Porous Ceramic Membrane

The McGill University team has discovered an innovative way to overcome this key challenge. Their solution involves creating a porous ceramic membrane, in place of the traditional dense ceramic plates that have been used in past designs. By introducing small amounts of polymer into the pores of this membrane, the team was able to eliminate the problematic interfacial resistance.

“By using a polymer-filled porous membrane, we can allow lithium ions to move freely and eliminate the interfacial resistance between the solid electrolyte and the electrodes,” explained George Demopoulos, who led the research.

This development is a major step forward for the industry. Not only does it improve the performance of the battery, but it also creates a stable interface that can support high-voltage operations—one of the key goals in the development of all-solid-state batteries.

How the Innovation Works

The issue of interfacial resistance has long plagued the development of all-solid-state batteries. As lithium ions travel through the battery, they encounter resistance at the interface between the solid ceramic electrolyte and the battery’s electrodes. This resistance limits the battery’s ability to efficiently deliver energy, ultimately reducing its overall performance.

To address this, the McGill University team created a porous ceramic structure that allows lithium ions to move through the material with less resistance. The porous structure alone was not enough to solve the issue, so the team filled the pores with a small amount of polymer. The result is a material that retains the stability and safety benefits of a solid-state battery but allows for more efficient ion movement, effectively solving the problem of interfacial resistance.

“This not only improves the battery’s performance but also creates a stable interface for high-voltage operation, one of the industry’s key goals,” said Demopoulos.

This advancement opens the door to a new generation of all-solid-state batteries that can operate at higher voltages, which is essential for achieving the long ranges and fast charging times that EV manufacturers are striving for.

Impact on the Electric Vehicle Industry

The implications of this breakthrough for the EV industry are significant. One of the primary barriers to the widespread adoption of all-solid-state batteries has been the issue of performance limitations caused by interfacial resistance. Now that this problem has been addressed, all-solid-state batteries are one step closer to becoming a commercially viable option for electric vehicles.

The development of safer, longer-lasting batteries is crucial for the growth of the EV market. As consumers demand longer ranges and faster charging times, the industry is looking for ways to improve battery technology without compromising safety. This breakthrough could help bridge the gap between these competing needs.

“Building the next generation of safer and more efficient batteries for electric vehicles is the ultimate goal,” said Senhao Wang, the first author of the study and a Ph.D. graduate from McGill University’s Department of Materials Engineering.

All-solid-state batteries have the potential to significantly extend the driving range of EVs by increasing energy density. In addition, their improved safety profile makes them an attractive option for automakers who are looking to build vehicles that meet stringent safety standards.

Challenges Ahead

While this breakthrough is a promising step forward, there is still much work to be done before all-solid-state batteries become widely available for EVs. The manufacturing processes for these batteries are still in the early stages of development, and scaling up production to meet the demands of the automotive industry will require further research and investment.

Additionally, while the elimination of interfacial resistance is a critical improvement, other technical challenges remain. For instance, finding ways to reduce the cost of materials and ensuring long-term stability under real-world conditions will be essential for the successful commercialization of all-solid-state batteries.

However, with continued advancements like the one made by McGill University researchers, the path to safer, more efficient electric vehicle batteries is becoming clearer.

Conclusion

The development of all-solid-state lithium batteries represents a significant leap forward in electric vehicle technology. The innovative work done by researchers at McGill University has brought the industry one step closer to achieving safer, longer-lasting, and more efficient batteries for EVs. By overcoming the issue of interfacial resistance with a porous ceramic membrane filled with polymer, this new design has the potential to revolutionize battery performance and enhance the safety of electric vehicles.

As the demand for electric vehicles continues to grow, breakthroughs like this will play a crucial role in shaping the future of the automotive industry. With safer, more efficient batteries on the horizon, the electric vehicle revolution is poised to accelerate even further, bringing cleaner, greener transportation options to consumers around the world.

Reference:

Senhao Wang et al, 4.8-V all-solid-state garnet-based lithium-metal batteries with stable interface, Cell Reports Physical Science (2024). DOI: 10.1016/j.xcrp.2024.102213